Martin Potter has joined BEKO TECHNOLOGIES to take up the role of General Manager. Martin has extensive sales and marketing management experience in the fields of pneumatics, drives and controls, transportation, process and automotive. He has a strong track record of achieving growth by the development of strategies, processes and high performing teams. Recent positions include Sales and Marketing Director at Phoenix Contact for 5 years and National Field sales Manager at SMC for 13 years.

Martin Potter has joined BEKO TECHNOLOGIES to take up the role of General Manager. Martin has extensive sales and marketing management experience in the fields of pneumatics, drives and controls, transportation, process and automotive. He has a strong track record of achieving growth by the development of strategies, processes and high performing teams. Recent positions include Sales and Marketing Director at Phoenix Contact for 5 years and National Field sales Manager at SMC for 13 years.

Martin has a BSc Hons degree from the University of Leicester in Business Administration and management. He is married to Diane and has 2 daughters Lucy and Rosie who are both keen competitive swimmers. Martin enjoys sports particularly mountain biking and running. He is currently building an AC Cobra in what limited spare time is available.

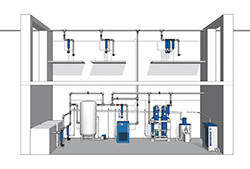

Virtually all manufacturing industry uses compressed air. There are some industries however where the quality of the compressed air is critical.

Virtually all manufacturing industry uses compressed air. There are some industries however where the quality of the compressed air is critical. BEKO TECHNOLOGIES theme for the Airtech Exhibition 2014 will be “solutions capability”. The company specialises in compressed air, gas and condensate conditioning and there will be a working demonstration of some of the key products for monitoring and saving energy within a compressed air system. There will be a challenge to visitors to the stand to use the solutions technology and to test their knowledge of compressed air purity. There will be a lucky person who will receive an iPad 16GB Wi-Fi chosen from all those who are successful at the challenge.

BEKO TECHNOLOGIES theme for the Airtech Exhibition 2014 will be “solutions capability”. The company specialises in compressed air, gas and condensate conditioning and there will be a working demonstration of some of the key products for monitoring and saving energy within a compressed air system. There will be a challenge to visitors to the stand to use the solutions technology and to test their knowledge of compressed air purity. There will be a lucky person who will receive an iPad 16GB Wi-Fi chosen from all those who are successful at the challenge. The uses of compressed air are pretty much universal from pumping up your car tyres to sophisticated control systems for industrial processes. In the medical sphere compressed air is used to operate simple mechanical devices such as drills and saws, ventilators and as a carrier gas in anaesthesia and inhaled medications. Compressed air at source is ambient air which has passed through a mechanical device(the compressor) which in industrial applications sometimes comes into contact with the lubricating oil. In more “quality” applications the compression chamber is usually dry of any lubricating medium.

The uses of compressed air are pretty much universal from pumping up your car tyres to sophisticated control systems for industrial processes. In the medical sphere compressed air is used to operate simple mechanical devices such as drills and saws, ventilators and as a carrier gas in anaesthesia and inhaled medications. Compressed air at source is ambient air which has passed through a mechanical device(the compressor) which in industrial applications sometimes comes into contact with the lubricating oil. In more “quality” applications the compression chamber is usually dry of any lubricating medium.  Compressors are responsible for 10% of all the power consumed in a mature industrial society like the UK and Ireland. Frequently 10% or more of this air will be wasted because of leakage caused by poor maintenance, bad design of air lines, acidic condensate attacking seals and joints just to name a few of the possibilities. Therefore it makes sense to do regular audits on the power consumed, flow, pressure, dew point and leakage as a starting point. Is this commonly done? Matthew Harrison, Regional Sales Manager at BEKO TECHNOLOGIES says, “No this type of extensive measurement is rare but smart companies are realising that you can’t know too much about what is happening within your compressed air network. You can avoid problems and be sure that you are operating to an efficiency that is acceptable if you regularly even better have a permanent output of key parameters within the system. Now that the BEKO Data Logger is available it is very easy for me and BEKO TECHNOLGIES colleagues to monitor up to 12 outputs per BDL installed which is plenty for the normal compressed air system.

Compressors are responsible for 10% of all the power consumed in a mature industrial society like the UK and Ireland. Frequently 10% or more of this air will be wasted because of leakage caused by poor maintenance, bad design of air lines, acidic condensate attacking seals and joints just to name a few of the possibilities. Therefore it makes sense to do regular audits on the power consumed, flow, pressure, dew point and leakage as a starting point. Is this commonly done? Matthew Harrison, Regional Sales Manager at BEKO TECHNOLOGIES says, “No this type of extensive measurement is rare but smart companies are realising that you can’t know too much about what is happening within your compressed air network. You can avoid problems and be sure that you are operating to an efficiency that is acceptable if you regularly even better have a permanent output of key parameters within the system. Now that the BEKO Data Logger is available it is very easy for me and BEKO TECHNOLGIES colleagues to monitor up to 12 outputs per BDL installed which is plenty for the normal compressed air system. A & B Air Systems and BEKO TECHNOLOGIES have helped lower costs at a leading European food manufacturer. Their customers are most of the leading high street food chains.

A & B Air Systems and BEKO TECHNOLOGIES have helped lower costs at a leading European food manufacturer. Their customers are most of the leading high street food chains. Compressed air is said to be responsible for approximately 10% of the power usage in the UK and other mature economies. BEKO TECHNOLOGIES are a leading company in the treatment of compressed air and management of condensates. Another major part of the business is measurement systems. BEKO TECHNOLOGIES are well equipped with experienced technical sales personnel to help businesses improve their efficiency of compressed air usage. We have put together a list of top tips:

Compressed air is said to be responsible for approximately 10% of the power usage in the UK and other mature economies. BEKO TECHNOLOGIES are a leading company in the treatment of compressed air and management of condensates. Another major part of the business is measurement systems. BEKO TECHNOLOGIES are well equipped with experienced technical sales personnel to help businesses improve their efficiency of compressed air usage. We have put together a list of top tips: In the field of condensate technology, there is also news at the COMVAC HANNOVER 2013 at BEKO TECHNOLOGIES: the upgrade version of the BEKOMAT 31, 32, and 33 condensate drains with improved serviceability.

In the field of condensate technology, there is also news at the COMVAC HANNOVER 2013 at BEKO TECHNOLOGIES: the upgrade version of the BEKOMAT 31, 32, and 33 condensate drains with improved serviceability.  At the COMVAC HANNOVER, BEKO TECHNOLOGIES presented the innovative variant of the EVERDRY FRA-V 2000C adsorption dryer. The special feature of this design is the modular concept, which allows for the separation of the adsorber containers from the pipework module, and for the reconnection in just a few steps. Through this structure, even larger plants can be packed in standard sea containers. This drastically reduces the transport and packaging costs and offers optimum protection to the plant during long sea journeys.

At the COMVAC HANNOVER, BEKO TECHNOLOGIES presented the innovative variant of the EVERDRY FRA-V 2000C adsorption dryer. The special feature of this design is the modular concept, which allows for the separation of the adsorber containers from the pipework module, and for the reconnection in just a few steps. Through this structure, even larger plants can be packed in standard sea containers. This drastically reduces the transport and packaging costs and offers optimum protection to the plant during long sea journeys. FAST

FAST