When a single piece of drum handling equipment fails, the whole operation feels it. Production slows, storage becomes congested, and schedules start to slip. The true cost of downtime includes not just hours lost, but also the ripple effect across safety, productivity and customer confidence.

Forbes reports that “unplanned/unscheduled downtime represents one of the costliest events at any industrial or manufacturing plant,” adding that “the average manufacturer confronts 800 hours of equipment downtime per year — more than 15 hours per week” (Sundeep V. Ravande in 2022). Even if your operation is smaller, a single hour of lost throughput in drum-handling can translate into thousands of pounds in strained logistics, idle shifts and lost opportunity.

For sites where drums are lifted, moved and stored every day, reliable equipment is essential. That’s why St Clare Engineering designs and builds every product with one clear goal: to keep your operation running smoothly, shift after shift.

The real causes of downtime in drum handling

Downtime rarely happens by chance. It usually creeps in through a few avoidable weak spots. Here are the main causes of downtime in drum handling operations:

Poor-quality attachments

Low-cost alternatives often look similar on paper but fail under real-world conditions. Forklift truck drum handling equipment that is not built to last can halt operations instantly and even pose a safety risk.

Lack of maintenance

If replacement parts are difficult to source or repairs rely on unresponsive suppliers, even a simple fault can take drum handling equipment out of service for days.

Safety incidents

Inappropriate or poorly maintained drum handling forklift attachments increase the risk of spills, drum damage and operator injury. Work must stop while investigations or clean-ups take place.

Inappropriate drum handling attachment

Many operators lose time simply because they are using the wrong attachment for the job. Drums vary in size, weight and material, and drum handing attachments must be selected to grip the precise style of drum safely and securely. Using an ill-fitting clamp or an attachment without the right load rating can lead to inefficient handling, damage to the drum or premature wear on the equipment.

How St Clare Engineering helps prevent downtime

St Clare Engineering takes a proactive approach to keeping customers moving. We help prevent downtime in your drum handling operations through:

Quality and reliability

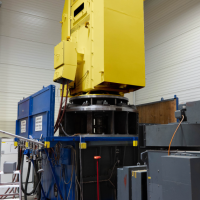

Every Grab-O-Matic attachment is engineered in the UK to high safety standards and using high-quality materials: designed to deliver years of safe, reliable performance. That reliability is built in from the start and backed up with dedicated service and support.

Fit for purpose

A key reason our drum handling products reduce downtime is the breadth of our range. We manufacture drum handling attachments to suit every environment and application: single and twin drum handlers, drum waist grippers, pedestrian drum handlers alongside our forklift-mounted drum handling attachments, and ATEX-rated drum handling equipment for use in hazardous areas. Our team helps each customer identify exactly the right tool for the job, preventing the wear and misuse that cause so many breakdowns.

Innovation to maximise efficiency

Innovation also plays a major role in saving time throughout the working day. Our bespoke quick-release system allows forklift operators to attach or detach drum handling equipment without leaving the cab. By eliminating the need to repeatedly climb on and off the truck, this unique design improves operator safety and cuts unproductive minutes from every task. Across a full shift, those small gains add up to a significant reduction in downtime.

Quick and effective maintenance and repair.

St Clare Engineering provides a complete servicing and repairs service, helping customers keep drum handling forklift attachments in peak condition and spot potential issues early. Because everything we supply is made and supported in the UK, spare parts are readily available and technical advice is only a phone call away.

Hire and rent drum handling equipment

If a fault does take equipment out of use, our hire and rental options ensure your operation keeps moving. We can supply a like-for-like drum handling forklift attachment from our rental fleet while repairs or replacements are arranged. This flexibility is especially valuable for customers who already rely on our servicing team, as it means production never needs to stop. Read more about our drum handling equipment rental service here.

From initial consultation to long-term maintenance, our goal is to give customers complete confidence in their drum handling equipment.

The benefits of reducing downtime

Reducing downtime delivers benefits that go far beyond the warehouse floor. Reliable equipment:

- keeps production schedules on track

- minimises costly repairs

- protects operators from unnecessary risk

- boosts morale, as teams can focus on the job rather than wrestling with faulty kit

- builds trust with customers through consistent, on-time performance.

When combined with St Clare’s flexible hire service, fast spare-part supply, and expert support, the result is a smoother, safer and more productive operation. Every hour saved from unplanned stoppages is an hour that adds value back into your business.

Keeping your drum handling operation moving

Downtime can be one of the most expensive challenges in any materials-handling environment, but it’s also one of the easiest to avoid with the right equipment and support.

St Clare Engineering’s British-made Grab-O-Matic drum handling equipment is built for reliability, supported by expert servicing, and available for hire whenever needed — helping you stay productive no matter what happens on the shop floor.

To discuss how our products and services could help reduce downtime in your operation, contact the St Clare Engineering team today.

Andy Bow – St Clare Engineering Ltd

Tel: 02380 643402

Fax: 02380 642189

Email: sales@stclare-engineering.co.uk

Web: www.stclare-engineering.co.uk